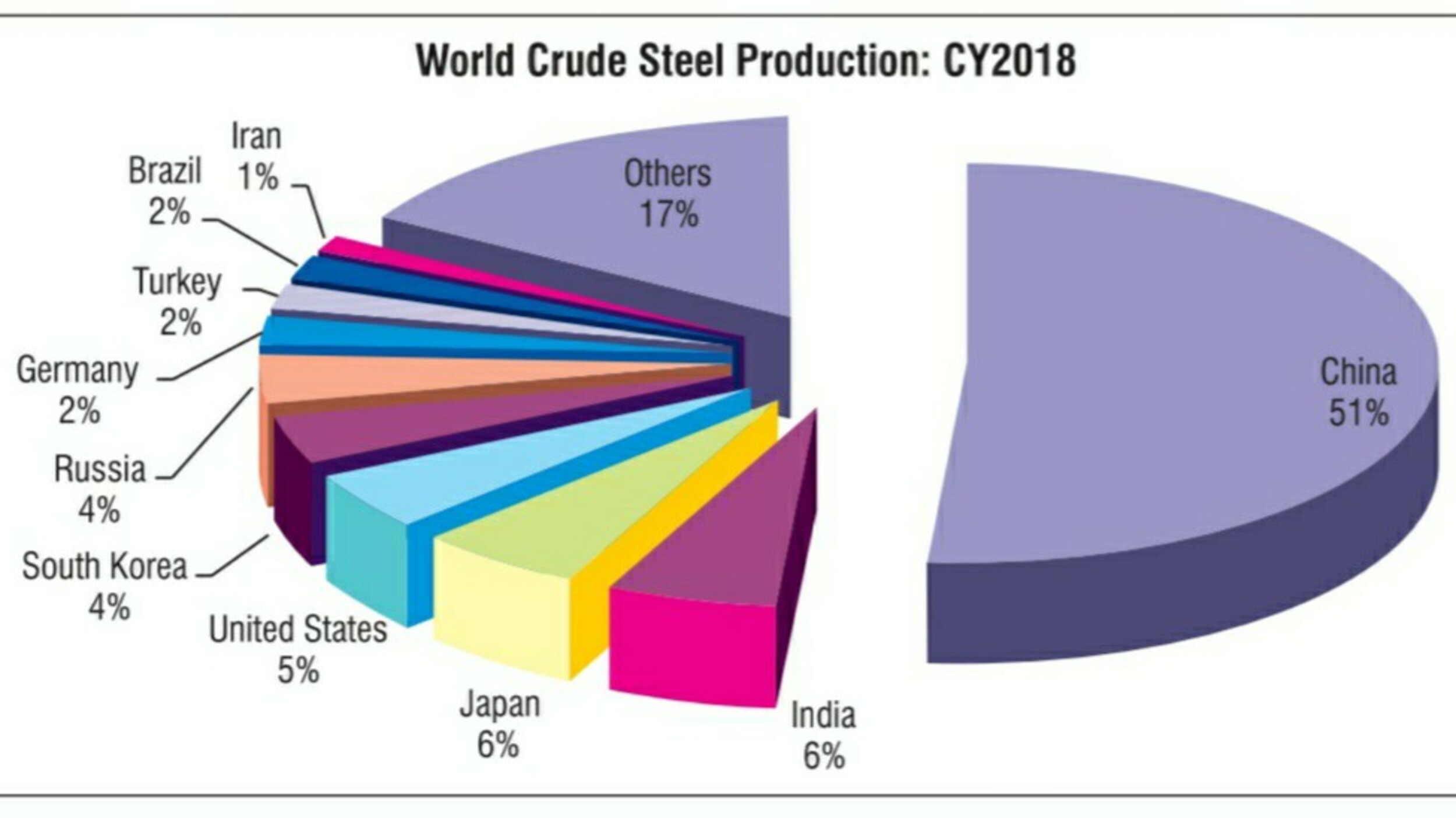

Steel Industry in India contributes around 2% of the country’s GDP and employs around 25 lakhs persons in steel/allied sectors. The global crude steel production in 2018 stood at 1,808.4 MTPA, growing by 4.5% as compared to 2017.

Steel industry Global

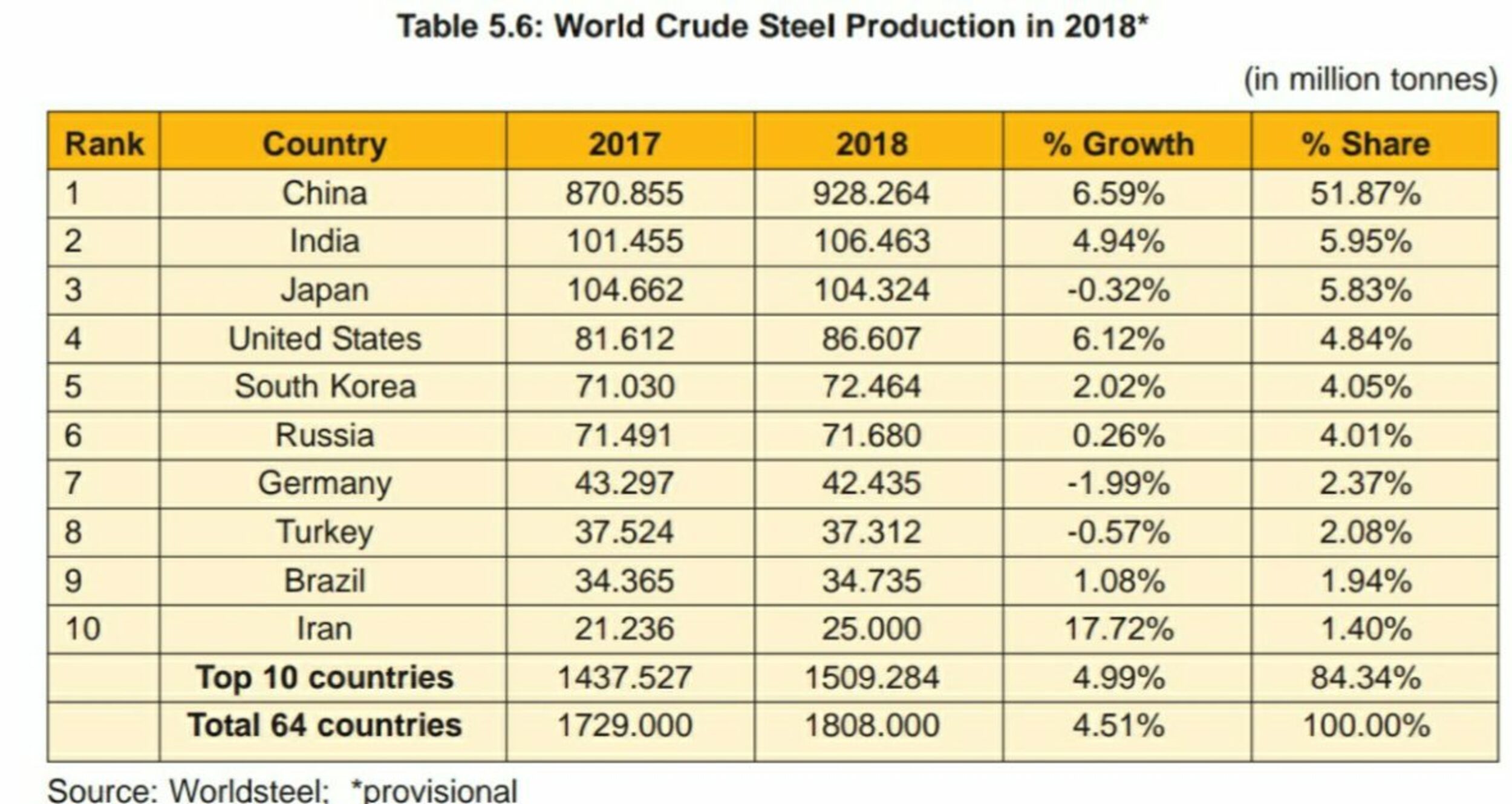

Europe, America, Africa, the Commonwealth of Independent States (CIS), the Middle East, Asia, and Oceania recorded an increase in Crude steel production. China, India, Japan, and the USA continued to be the top four countries in crude steel production in 2018, producing more than 67% of the world’s total steel output.

Chinese Crude Steel production reached 928 million tonnes during CY 2018, a growth of 6.59% over CY 2017. China remained the largest Crude Steel producer in the world, accounting for 74% of Asian and 52% of World Crude Steel production during CY 2018.

Steel Industry in India has become the world’s 2nd largest producer of crude steel in the calendar year 2018, producing 106.464 Million Tonnes (MT) (prov.) crude steel with a growth rate of 4.94% over 2017.

Steel Industry in India is the largest producer of Direct Reduced Iron (DRI) or Sponge Iron in the world, producing 30.368 MT (prov.) Sponge Iron in 2018 with a growth rate of 3% over 2017. The country is also the 3rd largest consumer of finished steel in 2018 [96MT (prov.)] in the world preceded by China (835MT) and USA (100MT).

Steel Minister

- Dharmendra Pradhan

Steel Industry in India

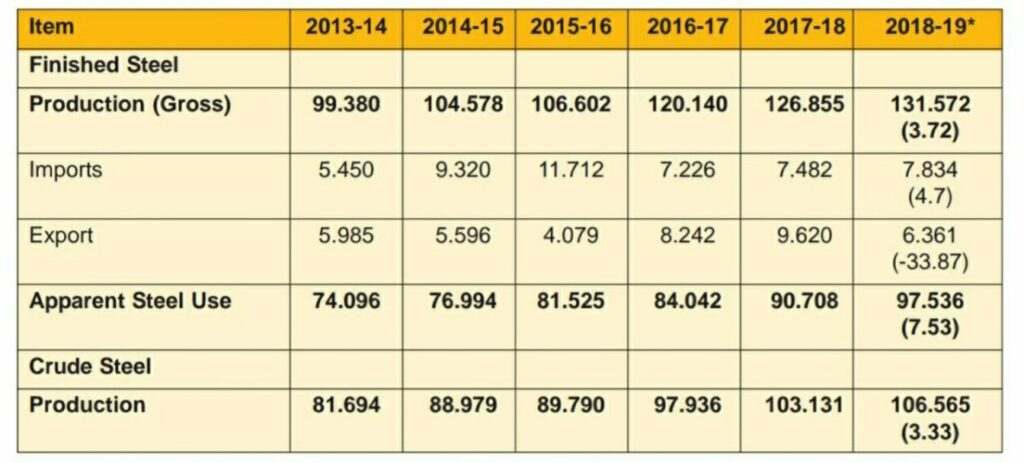

Steel Industry in India contributes around 2% of the country’s GDP and employs around 25 lakhs persons in steel/allied sectors. Production of crude steel was at 106.565 million tonnes, a growth of 3.33% compared to the same period of last year.

Capacity for domestic crude steel production expanded from 102.26 MT in 2013-14 to 137.97 MT

in 2017-18, a CAGR growth of 6.17% during this five-year period (Data on capacity utilization in

2018-19 is yet to be finalized). Steel Industry in India Crude steel production grew at 3.67% annually (CAGR) from 88.979 million tonnes in 2014-15 to 106.565 million tonnes in 2018-19 (prov.).

SAIL, RINL, TSL, Essar, JSWL & JSPL together produced 63.602 million tonnes during 2018-19 which was a growth of 7.1% compared to the same period of last year and 62% of total crude steel production. The rest 38% i.e. 42.962 million tonnes came from the Other Producers, which was a decline of 1.8% over the same period of last year.

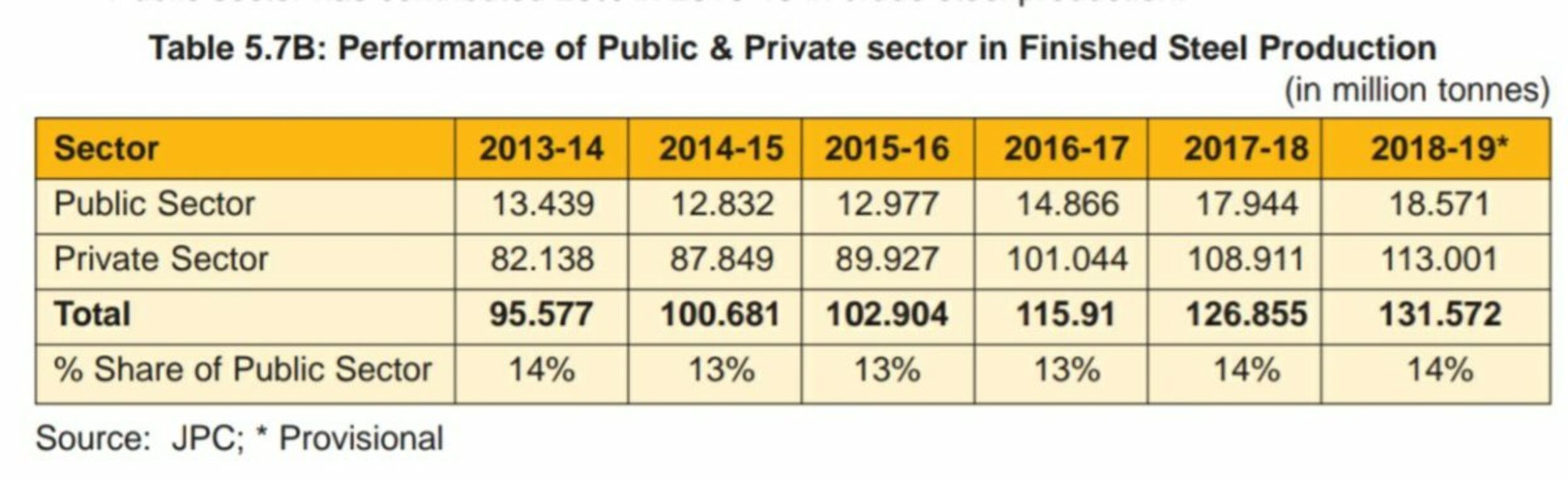

Production stood at 131.572 million tonnes, a growth of 3.72% compared to last year. Exports stood at 6.361 million tonnes, a decline of 33.87% compared to last year. Imports stood at 7.834 million tonnes, a growth of 4.7% compared to last year.

India was a net importer of total finished steel. Consumption stood at 97.536 million tonnes, a growth of 7.53% compared to last year.

Steel Ministry

The Ministry of Steel is under the charge of the Minister of Steel and is assisted by the Minister of State for Steel. The Ministry is responsible for planning and development of iron and steel industry, development of essential inputs such as iron ore, limestone, dolomite, manganese ore, chromites, Ferro-alloys, sponge iron, etc. and other related functions.

Ministry of Steel Functions

- Facilitate an increase in steel usage in the country to create demand of Steel and thereby to facilitate an increase in steelmaking capacity.

- Facilitate growth in steel production to meet increased steel consumption/demand.

- Facilitate adequate availability of raw materials for the steel industry particularly iron ore and coal for PSUs.

- To strive for improvement in the performance of the Iron & Steel industry including R&D and Technology interventions, Quality Control Orders and improvements in techno-economic parameters. Policy Initiatives needed for the steel sector.

- Monitoring performance of CPSEs: Against MOU targets, CAPEX and Implementation of large projects.

- Safety in the steel industry.

- Coordination with Department of Commerce on issues concerning: export/import & trade matters relating to iron ore/manganese/chromium; taxation and policy for import and export duty on steel products and International Trade issues (anti-dumping duty, safeguards, countervailing, etc.)

Steel Plants in India

Visakhapatnam Steel Plant

Visakhapatnam Steel Plant (VSP) is a 7.3 MTPA plant. It was commissioned in 1992 with a capacity of 3.0 MTPA of liquid steel. Rashtriya Ispat Nigam Ltd. (RINL) subsequently completed its capacity expansion to 6.3 MTPA in April 2015 and to 7.3 MTPA in December 2017. RINL is one of the major players in the country for Long Products.

Salem Steel Plant

SAIL has three special and alloy steels plants viz. Alloy Steels Plant at Durgapur (West Bengal), Salem Steel Plant at Salem (Tamil Nadu) and Visvesvaraya Iron and Steel Plant at Bhadravati (Karnataka). Salem Works A total of 6 projects relating to process, energy, and product optimization have been completed. Two collaborative projects have been initiated with academic institutions.

Steel Authority of India Ltd undertook modernization & expansion of its Integrated Steel Plants at Bhilai, Bokaro, Rourkela, Durgapur, Burnpur and Salem Steel Plant.

India steel Company

Here are the Top Companies in the steel industry in India. The Rank list is based on sales in the year 2019.

1. Tata Steel Ltd

3. Steel Authority of India Ltd Read More About Top Company in Steel Industry